In this small picture book we describe the history of the company A.V. Branth - deliberately simplified, short and clear (created in 2014).

Foundation of A.V. Branth by Arnold Valentiner=Branth to develop products that significantly extend the service life of steam engines.

The basis for this was his experience with rust and mold formation during the operation of the first steam dairies in Denmark and the selection of overseas raw materials at the import and port location of Hamburg.

Start of supplying anti-mould wall paint to dairies and a few years later the first "permanent paint" for rust protection.

Over the years, the customers for Branth's special paints were almost exclusively dairy processing companies. Through diversification, other products for dairies and cheese dairies were also offered, e.g. the well-known "butter color" (natural carrot base), which made butter look tastier.

In addition to the existing dairies, Branth's protective paints were now also supplied to the beverage industry, food industry and government agencies. In the following years, the focus was on the all-purpose cleaning agent "Brantholin", as paint production was only possible to a very limited extent until the early 1950s due to raw material restrictions.

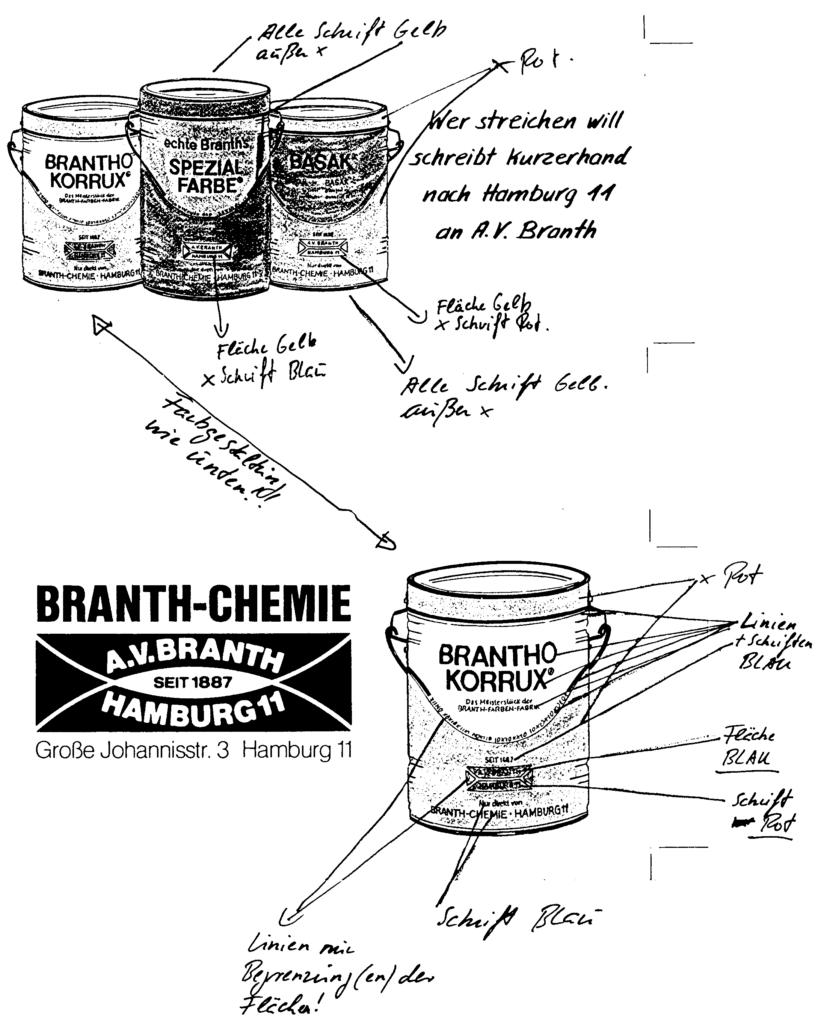

Building on decades of experience with customers and after years of intensive development work with the latest raw materials, the first "Brantho-Korrux" was introduced (known today as "Brantho-Korrux Normal"): A lead-free thick-film anti-corrosion coating material with penetrating properties that could be used as a primer and finish coat and could be painted several times on top of each other without the risk of subsequent flaking.

Substantial expansion of production. The Branth-Farben-Fabrik was the first paint factory in Northern Europe to start production at the Erdmannstraße site with the most modern closed bead mills (instead of the roller mills used until then).

From this year onwards, Brantho-Korrux could be advertised as having over 100 hours of resistance in the aggressive "salt spray test". For over a decade, it had not been possible to break through this magic barrier; today, Brantho-Korrux "3 in 1" has a resistance of over 1,400 hours in the same test.

100th anniversary of the company. Invention of Brantho-Korrux 3 in 1, which combines the properties of easy processing, very high corrosion protection and high environmental compatibility and has revolutionized the market for anti-corrosion paints. The greatest recognition has been the copying of the term "3in1" by numerous market companions since then. A term that unfortunately cannot be protected due to its designation.

Recruitment of employees in the former GDR. As a result, considerable sales were made there in the first few months after the border was opened. In previous years, all key products had been quality-tested by TÜV and the quality management system had been audited by TÜV.

Last changeover to encapsulated production processes and switch to completely hazardous waste-free production. Corresponding chemical substances are recycled and reused within the production cycle. Conversion to emptyable cans with "Green Dot".

Conversion of the energy supply to CO2-neutral electricity

.In March 1996, our production is the first independent company in Hamburg to be certified in accordance with the EC Eco-Audit Regulation; during the revalidation in April 1999, we are also certified in accordance with DIN EN ISO 14001. This demonstrates that not only our products are highly environmentally friendly, but also our entire production process.

Offer of the "economy lid system". Evaporation losses from opened cans are reduced by 80-90%, most customers can now save themselves the trouble of washing brushes.

After 15 years of often depressing experiences in the development of water-thinnable metal protection paints, since this year we can now offer a successful product with Brantho-Korrux "ecopakt", which is almost completely solvent-free and which is successfully used for repairs, one-off productions and in industrial series production.

The company moves from Hamburg to Glinde in order to further expand the development area in addition to production. There is also a direct connection to the A24 motorway.

Further expansion and modernization of production and development

Celebration of the company's 125th anniversary

.

Testing and certification of Brantho-Korrux 3 in 1 that it is so safe that it can be used to paint toys (SIN EN 71-3) and at the same time offers such a high level of protection that it provides long-term protection for oil rigs in the Atlantic (NORSOK, CX)

Invention of the first spray can (comfort can) with double active ingredient and CO2-neutral compressed gas

Introduction of heating with CO2-neutral energy. In addition, implementation of free e-charging stations for all employees and visitors.

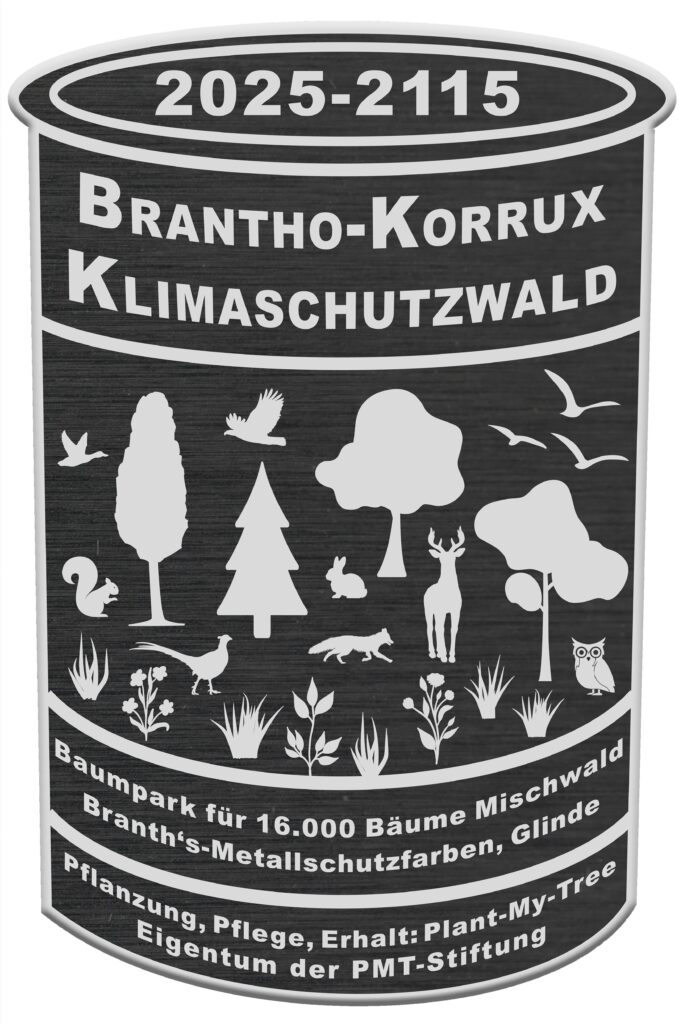

Start of investment in various forest reforestation projects and wind power promotion, with the aim of being able to sell our products CO2-neutrally across the entire supply chain. Our own production has already been CO2-neutral for 2 years.

EPD certification of the Brantho-Korrux 3 in 1 with a share of less than 2kg CO2 per kg of manufactured paint quantity in relation to the entire supply chain (raw material extraction, production, transportation, etc.). By investing in our own climate projects (no conversion payments for third-party projects), this proportion is already less than 1kg CO2.

All products in the range can be offered as CO2-neutral products